A multinational medical device contract manufacturer of stents, balloons, and catheters needed to easily shift manufacturing lines across its multiple facilities from development to mass production. Each facility was doing the same type of work and it was necessary to maintain precision and accuracy as demand increased. The manufacturer contacted Omron (Hoffman Estates, IL, USA; www.automation.omron.com/en/us) for an integrated solution that would help with speed and consistency of labeling across its many facilities.

Label accuracy is imperative in the medical device industry, as any incorrect information can lead to fines, recalls, and a reduction in consumer confidence. To comply with Food and Drug Administration (FDA) unique device identifier (UDI) standards, all medical device manufacturers are required to format their labels in a specific way so that end users can easily identify package contents. This includes a UDI that must be issued through an FDA-accredited agency.

Personnel at the manufacturer’s facilities were attempting to inspect label quality manually via 200% visual inspection (meaning you need two sets of human eyes) as well as spot checking with an offline device. The main reason for implementing the new integrated vision system was to ensure global UDI compliance across a variety of products for the medical device industry. The system needed to verify the contents of the label as well as the quality of the label and record the data for each unique (individual) product. The new system ensured that the customer met global UDI compliance and increased speed by freeing up human operators from doing tedious tasks.

The FDA UDI Rule, as listed in CFR 21 Part 801.20, requires that medical devices need to be labeled with a unique ID, provided by an FDA-accredited issuing agency such as GS1, in the form of a barcode. To comply with the GS1 General Specification, the quality of the barcode on the label must be tested using ISO 15426 certified verifiers, achieving a minimum 1.5 grade to ISO 15415/15416 and have the proper GS1 data format. Further, FDA CFR 21 Part 820.120 states that medical device labels must be inspected for accuracy and correctness.

The FDA UDI mandate also requires barcodes to be of a certain quality threshold to help ensure they will be readable throughout the supply chain. Any barcode reader can validate whether a code is readable, but simple validation is not enough to guarantee a passing grade. It is possible to grade barcodes manually if volumes are small and the inspection team is well trained on the changing standards. However, it becomes unmanageable once manufacturing starts being moved between facilities for a larger variety of products that each have unique requirements.

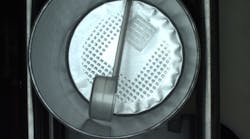

The hardware chosen to solve this problem, the Omron LVS 7510, features a line scan camera that integrates directly into industrial printers. Included with the hardware is proprietary software, so this combination functions as an off-the-shelf solution.

Jason Mack, Strategic Account Manager-Life Science, Omron Automation Americas, says "The customer chose this solution because it is a fully compliant, all-in-one solution. Omron offers an Installation Qualification/Operation Qualification/Production Qualification (IQ/OQ/PQ) package to validate the system when it is initially installed." This is important, he says, because the customer operates in a heavily regulated industry. "IQ/OQ/PQ is required in most 'validated environments' as part of the initial commissioning of a new piece of equipment," says Mack. "Omron offers a set of IQ/OQ/PQ documents that help an end user integrate it into their production environment. The customer also chose this system because it is a fully integrated, packaged system and not a piecemealed system, which allowed the manufacturer to roll it out to global facilities without worrying about whether the systems were the same."

Omron’s system creates templates for each requisite label format that can then be saved in the cloud and accessed across all facilities. This helps transitions flow seamlessly from one facility to another and guarantees that every label produced meets a global standard created by a team of experts in these regulations.

Mack explains that as labels exit the printer, the label images are scanned and stored by a 400-ppi CMOS monochrome high-speed line scan camera. "The camera is available in two lengths to accommodate 4-inch and 6-inch printer widths. The software takes the scanned images and grades them according to ISO 15415/ISO 15416 standards. The system also validates the optical character recognition (OCR) as well as an overall golden image comparison to guarantee every label in the run meets the standards and specifications.

"Proprietary software includes OCR that allows the user to compare human readable information in printed alphanumeric characters with information that is encoded in the barcode, helping confirm that the human readable information is correct and readable. This setup allows the system to run at full printing speed and pauses and alerts the operator whenever there is an error detected. Changeover between label templates of varying sizes requires nothing more than opening a saved template. This means the customer can run a 10-in. label and then switch to a 2-in. label in less than a minute avoiding significant downtime."

The system inspects barcode quality and the data contained in the barcode. It inspects human readable text for data and quality. It also looks for voids, smears, over- and under-printing, sharpness, contrast, and positioning on the label. Omron’s LVS 7510 checks each label to ensure that the barcode is of the minimum quality required by the FDA UDI mandate.

Because this is an out-of-the-box, fully integrated system and was designed for this type of task, there were no challenges experienced during or after installation.

The customer was able to immediately implement the system and begin designing label templates for its other locations. Two operators who had been working on label instruction were able to move their focus to other tasks, and the concern about faulty labels diminished. The manufacturer will continue to implement this solution across multiple facilities as well as other contract manufacturing sites.

Since installing this system, the customer has not allowed any defects to pass through, protecting the brand in the market as well as consumer safety. It has also been able to increase productivity by allowing operators to focus on other activities while the system is running.

It is important to understand the needs of the industry as a whole when implementing a system like this. Many other solutions offer pieces of the system, and customers believe they are easy to install. However, they quickly find that it is hard to install a complete system.

When customers create “custom” systems they face hurdles like CFR21 Part 11 compliance, label change-over, validation, and ongoing compliance as standards change. The Omron system handles all of these in one off-the-shelf system.